Freestone Advisory EN

Freestone Advisory EN

Freestone People EN

Freestone People EN

Aleris, world leader in the production and sale of aluminium rolled products, asked Freestone to assist them in drawing up a master plan and to guide them in the step-by-step implementation of it. In recent years, the focus was mainly on the turnover and profitability of the company. Now Aleris wants to make up the backlog in terms of infrastructure.

In a first step towards a master plan, the pain points of the current infrastructure and layout were listed. Then, the outlines of the master plan were drawn.

For example, the number of office buildings had to be reduced, taking into account current benchmarks in terms of space utilisation and standards. The modern arrangement of all personal infrastructure was to be used not only as a change enabler for staff, but also as a marketing tool for customers and visitors. The unique capabilities of the company in terms of production processes and products should be reflected in the infrastructure.

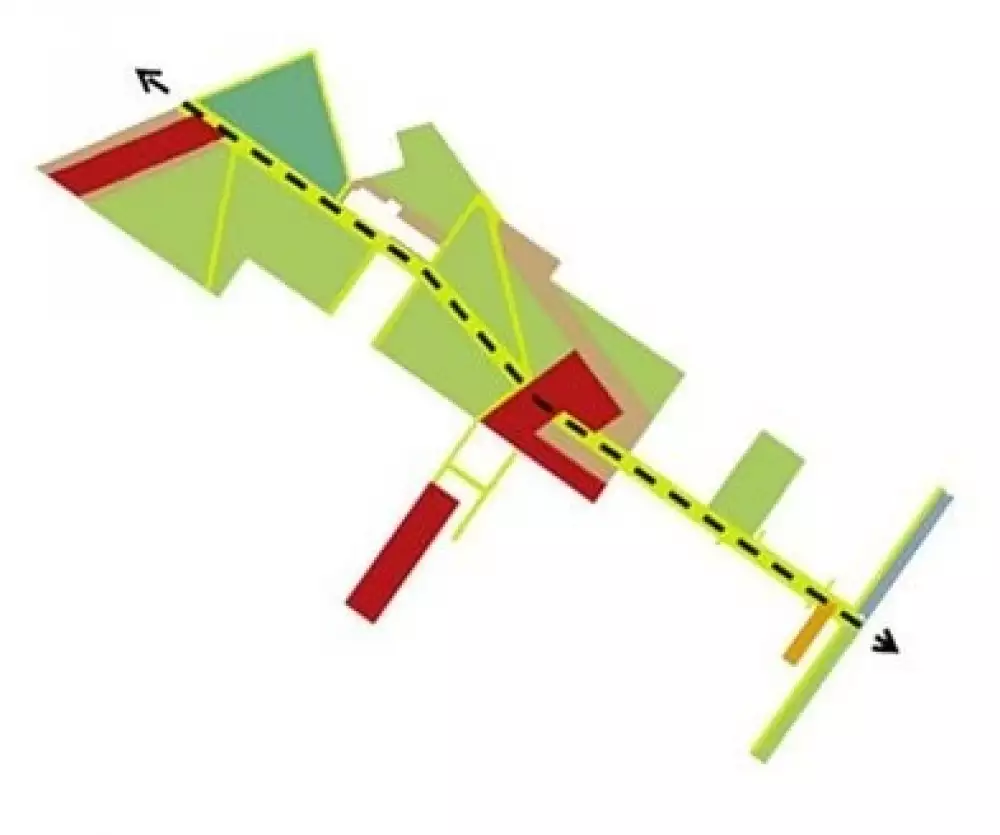

The 'backbone' of the master plan is the main route that crosses the site from the quay to the street. It is the connection between the central beating heart (factory entrances, refectory, sanitary facilities and operations) and the new NAG building. This route provides orientation. From this backbone, every location on the site is accessible.